The manufacturing floor is transforming like never before, thanks to advanced technologies. According to Gartner, by 2026, at least 70 percent of multinational organizations will have implemented AI-driven solutions to significantly enhance operational efficiency. (Source: Gartner).

Agentic AI is a strong AI class capable of proactive decision-making, problem-solving, and adaptive learning. Agentic AI in manufacturing takes autonomy to a new level, directly impacting production, quality, and innovation—unlike conventional AI, which often requires human supervision.

Imagine the major automakers using Agentic AI to streamline manufacturing processes and quickly react to disturbances without human intervention.

Alternatively, pharmaceutical behemoths use innovative technology to proactively predict equipment breakdowns, lowering downtime by up to 40 percent. These events are no longer hypothetical; Agentic AI is already proving its manufacturing capabilities.

As global businesses grow more competitive, manufacturers embracing this new paradigm will flourish, attaining operational excellence, agility, and continuous innovation. In this blog, we will discuss why Agentic AI is a buzzword and necessary investment for progressive manufacturing companies.

What is Agentic AI in Manufacturing?

Agentic AI works autonomously, making judgments and continuously learning and adapting without human intervention. This marks a significant leap over standard AI and conventional automation, enabling real-time, self-directed, intelligent decisions that proactively address operational inefficiencies, quality concerns, and production bottlenecks.

Leveraging machine learning, deep learning, natural language processing, and computer vision, Agentic AI acts as a dynamic partner in manufacturing, enhancing manufacturing efficiency and quality control.

Leading smart factories are proactively deploying Agentic AI into critical applications, including:

- Autonomous production process adjustment in real time to lower waste and downtime.

- Predictive maintenance to detect early machine failure and reduce production delays.

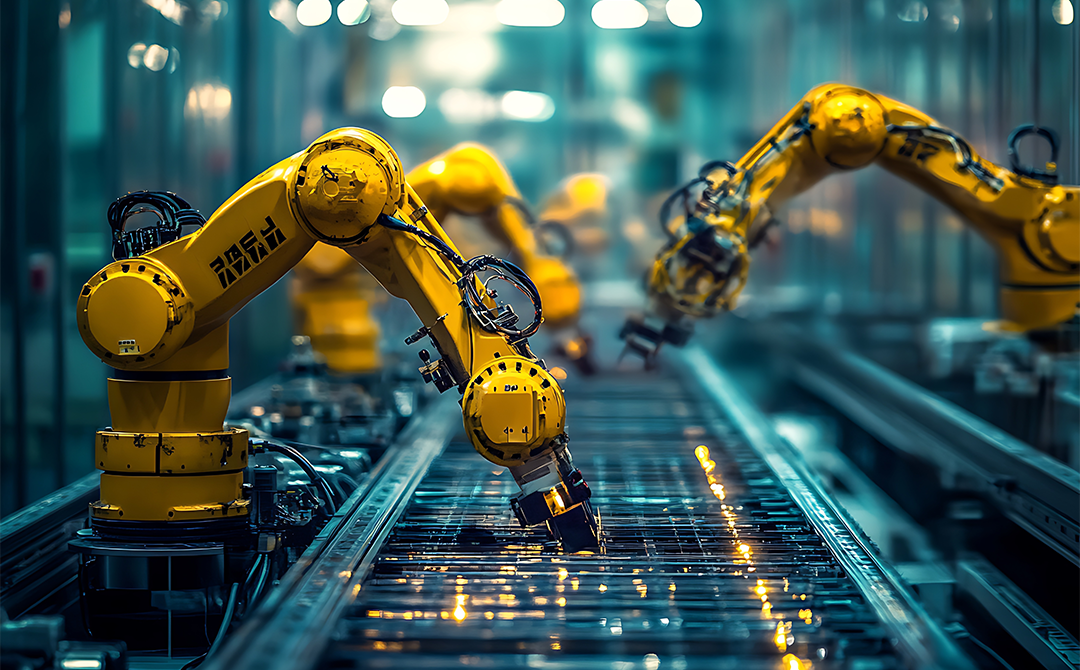

- Advanced robotic automation, where robots independently analyze their environments and adjust actions to improve efficiency and safety.

Agentic AI enables companies to operate faster and smarter, transforming factories into agile, high-performing environments that drive lasting competitive advantage.

Is Agentic AI in Manufacturing Just a Trend or Business Essential?

Agentic AI in manufacturing is far more than just a fleeting technological trend. It is quickly becoming a business necessity to strive for operational excellence, remain resilient, and achieve sustainable success in today’s competitive environment. It is widely recognized that companies prioritizing AI-driven technologies routinely outperform their competitors.

Manufacturers today are under immense pressure to lower expenses, improve manufacturing techniques, and raise product quality. Agentic AI satisfies these demands by spotting inefficiencies, proactively addressing operational interruptions, and resource optimization without continuous human supervision.

The ability of the technology to adjust and learn from fresh data in real time helps companies react quickly to demand variations, market changes, and unanticipated events.

Why Smart Manufacturing Companies are Investing in Agentic AI (And You Should Too)

Smart manufacturing enterprises are investing significantly in Agentic AI for a simple reason—it delivers measurable and rapid returns on investment. According to a report by Accenture, organizations leveraging AI-driven technologies have experienced reductions in operating costs and improvements in process efficiency. (Source: Accenture)

This is not just technological advancement but a strategic decision geared toward long-term business resilience and profitability.

Manufacturing leaders are increasingly recognizing the value of Agentic AI due to the following reasons:

- Enhanced Decision-Making: Agentic AI provides real-time analytics and predictive insights, empowering companies to make faster, data-driven decisions without manual intervention.

- Improved Operational Efficiency: Autonomous systems identify bottlenecks, proactively manage inventory, and optimize resource allocation, significantly reducing waste and enhancing productivity.

- Increased Scalability and Agility: AI-driven processes allow factories to adapt production schedules quickly, manage demand fluctuations, and seamlessly scale operations without extensive human oversight.

- Proactive Maintenance: Through predictive analytics, Agentic AI reduces unplanned downtime by predicting equipment failures, improving overall production reliability.

The Challenges of Adopting Agentic AI in Manufacturing

While Agentic AI holds transformative potential for manufacturing, it also brings a unique set of challenges. Organizations must navigate technological, organizational, and strategic obstacles to realize their advantages.

A McKinsey study indicates that 70 percent of AI projects face obstacles—such as data quality, infrastructure preparedness, and worker adaptation—that hinder adoption. (Source: McKinsey)

Here are some common challenges manufacturers face:

- Data Integration Complexities: Agentic AI needs huge volumes of high-quality data to function effectively. However, legacy manufacturing systems often face issues like data silos, fragmentation, and inconsistent standards.

- High Initial Investment: Agentic AI deployment requires huge upfront expenses, including infrastructure upgrades, talent acquisition, and people training.

- Skill Gap: Many manufacturers lack internal expertise in AI and machine learning, creating dependency on external partners or consultants, which can slow down implementation timelines.

- Resistance to Change: Employees accustomed to traditional manufacturing processes might resist AI-driven automation, fearing job displacement or uncertainty regarding roles in the new environment.

- Security and Compliance Concerns: Integrating autonomous systems into existing operations raises cybersecurity concerns and compliance challenges, especially in highly regulated industries such as pharmaceuticals or aerospace, where data privacy and security are crucial.

Addressing these challenges requires a strategic, phased approach, beginning with clearly defined use cases, targeted training programs, and carefully selected technology partners to ensure smooth integration and lasting success.

An Expert’s Approach to Agentic AI in Manufacturing

Agentic AI deployment in manufacturing requires a strategic vision shaped by professional advice and best practices. Leaders must underline the need to use a disciplined, planned approach when combining Agentic AI to maximize ROI and reduce risk.

A recommended expert approach to deploying Agentic AI:

- Identifying High-Value Use Cases First: Start with particular use cases that promise exact, measurable results such as predictive maintenance, inventory optimization, or autonomous process management. This guarantees faster returns and generates momentum for better acceptance.

- Ensuring Data Readiness: Industry experts emphasize that the success of Agentic AI hinges on the availability of clean, accurate, and well-structured data. They recommend conducting thorough data audits and implementing string data management frameworks early in the process to ensure the AI models perform reliably and at scale.

- Creating a Cross-Functional Team: Experts recommend forming a dedicated team that brings together technology leaders, operations managers, and data scientists. This collaboration ensures that Agentic AI solutions are not only technically sound but also deeply aligned with real-world business priorities and production needs.

- Continuous Monitoring and Refinement: According to AI specialists, Agentic systems thrive on real-time learning and iteration. It is essential to implement strong monitoring frameworks and continuous feedback loops. As a result, this enables the AI models to evolve, stay effective, and remain in sync with shifting enterprise objectives.

With this expert-led, structured approach, you can seamlessly integrate Agentic AI into your processes, unlocking operational efficiencies, and strategic benefits.

The Best Applications of Agentic AI in Manufacturing

Addressing complex challenges and enhancing productivity, Agentic AI is revolutionizing manufacturing operations. Its applications span numerous critical areas, helping businesses achieve unprecedented operational efficiencies. According to Fluid AI, Agentic AI implementations have significantly streamlined key processes, from shop-floor management to global supply chains. (Source: Fluid.ai)

Below are some of the most impactful applications of Agentic AI in manufacturing:

- Predictive Maintenance: Real-time data allows agentic AI to forecast machine faults, arrange preventative maintenance, and reduce unexpected downtime, extending equipment lifetime and dependability.

- Quality Control and Inspection: AI-driven vision systems independently find product flaws and deviations, lowering manual checks and raising accuracy. This usually raises product quality by 20 to 30 percent.

- Supply Chain Optimization: Agentic AI autonomously analyzes market trends, demand forecasts, and logistical constraints to streamline inventory management, reduce carrying costs, and enhance responsiveness to supply disruptions.

- Autonomous Robotics and Factory Automation: Intelligent robotics integrated with Agentic AI dynamically adapt to real-time production demands, independently performing tasks from assembling components to packaging finished products, significantly reducing human intervention.

- Energy and Resource Optimization: Agentic AI independently monitors and adjusts energy usage and resource allocation, reducing waste and operational expenses. Factories deploying such solutions have recorded up to 25 percent lower energy costs.

- AI-Driven Inventory Forecasting: Agentic AI improves demand forecasting accuracy by analyzing real-time sales trends, seasonal patterns, and external disruptions. It autonomously adjusts inventory levels, reducing both stockouts and overstocking.

- Digital Twin Integration: One of the most advanced use cases of Agentic AI in manufacturing is its synergy with digital twin integration. By creating virtual replicas of physical assets, Agentic AI continuously learns from and interacts with these digital models. This integration allows AI agents to simulate various production scenarios, test process changes, and identify potential inefficiencies before they occur in the real world.

These advanced applications underline why manufacturers increasingly rely on Agentic AI, positioning their operations for growth, agility, and sustained competitive advantage.

Proven Examples of Agentic AI in Manufacturing at Work

Real-world deployments illustrate the transformative impact of Agentic AI in manufacturing environments. These proven examples demonstrate its tangible benefits:

- BMW’s Intelligent Robotics and Automation: At its manufacturing plants, BMW employs agentic AI to enable autonomous robots that independently spot bottlenecks, make proactive decisions, and change manufacturing processes. (Source: BMW)

- General Electric’s Predictive Maintenance Initiative: GE leveraged Agentic AI across its aviation manufacturing sites to monitor machinery and detect potential equipment issues without human intervention.

- Siemens Autonomous Supply Chain Management: Siemens AG adopted Agentic AI to optimize its complex supply chain, enhancing real-time inventory management. AI agents independently make supply chain practices based on evolving demand signals, reducing inventory holding costs by nearly 20 percent and improving response times. (Source: Siemens)

- BMW Group’s Quality Inspection: BMW Group implemented an Agentic AI-driven visual inspection system to automatically detect defects in automobile parts. This dramatically improved flaw detection accuracy and minimized manual inspection time, enhancing product quality and lowering customer returns. (Source: BMW)

- Fanuc's Autonomous Robotics: Fanuc utilizes Agentic AI for robotics in its factory automation solutions. These autonomous robots dynamically optimize tasks like material handling and assembly workflows, reducing human intervention by approximately 25 percent and enhancing factory productivity and reliability. (Source: Fanuc)

Proven use cases show the power of Agentic AI. Milky Way takes it further with enterprise-scale automation and smarter decisions.

What to Expect from Agentic AI in Manufacturing in the Next Decade

Agentic AI will revolutionize manufacturing in ways we are only starting to realize. Manufacturing processes will undergo radical changes as technology develops and industry acceptance picks up pace. Research shows that Agentic AI would enable factories to reach up to 40 percent increases in operational efficiency and drastically lower labor costs using considerable automation by 2034. (Source: Research)

Here's what manufacturing leaders can expect from Agentic AI in the coming decade:

- Increased Factory Autonomy: Agentic AI will become sophisticated enough to independently manage entire production lines with minimal human intervention, autonomously adapting to real-time market demands and changes in supply chain conditions.

- Advanced Human-AI Collaboration: Perfect coordination between human workers and autonomous AI agents will define future factory floors. AI will take care of repetitive, high-risk jobs, allowing human teams to concentrate on innovation, strategy, and high-value projects.

- Hyper-Personalized Manufacturing: Hyper-personalization at scale driven by Agentic AI will allow manufacturers to modify manufacturing lines to fit individual consumer preferences quickly, enabling autonomy. This agility will be competitive, particularly in automotive, consumer electronics, and healthcare.

- Enhanced Sustainability and Circular Economy Initiatives: Intelligent AI agents will independently maximize resource use, drastically lowering energy usage and waste. Leveraging Agentic AI, manufacturers may radically reduce their carbon footprints, establishing themselves as leaders in the sustainable sector.

- Real-Time Supply Chain Management: With advanced predictive analytics, Agentic AI will autonomously manage global supply chains in real time, adapting to disruptions instantly and ensuring minimal delays or inventory wastage.

The next decade will witness Agentic AI becoming an indispensable competitive advantage, reshaping the manufacturing industry through unparalleled efficiency, innovation, and sustainability.

How to Get Started with Agentic AI in Your Manufacturing Workflow

Adopting Agentic AI may seem daunting, especially for manufacturers transitioning from traditional systems. However with a phased and strategic approach, organizations can gradually unlock their transformative potential while mitigating risk.

Here’s a practical step-by-step guide to help manufacturers get started:

1. Identify Business Objectives and Use Cases

Start by clearly defining what you want to achieve. Whether it’s reducing downtime, improving quality control, or optimizing energy consumption, setting tangible goals will help prioritize the right Agentic AI use cases. Focus on low-hanging fruit like predictive maintenance or anomaly detection to generate early success.

2. Assess Your Data Readiness

Agentic AI relies heavily on clean, structured, and real-time data streams. Conduct a data audit to identify gaps in quality, integration, or accessibility. Ensure that your sensors, IoT systems, and data pipelines are equipped to feed continuous data into the AI framework.

3. Choose the Right Tools and Partners

Select AI platforms or solution providers that specialize in manufacturing-specific use cases. Collaborating with experienced AI vendors ensures the technology is tailored to your production environment and integrated seamlessly with your existing infrastructure.

4. Build Internal Capabilities

Empower your workforce by offering training in AI literacy and tools. This encourages adoption and helps cross-functional teams such as engineering, operations, IT for collaborating effectively with AI agents.

5. Start Small, Scale Fast

Launch pilot projects in one plant or production line and monitor performance, gather feedback, and use what you have learned to refine your AI model. Once the pilot proves ROI, scale the solution to other areas of the plant or across global operations.

6. Implement Continuous Learning and Governance

Establish feedback loops, KPIs, and governance frameworks to monitor agent performance, ensure compliance, and continuously improve the system's decision-making abilities.

Unlocking the Full Potential of Agentic AI in Manufacturing

As the manufacturing industry evolves, adopting Agentic AI is no longer an option but a strategic need for companies trying to remain competitive. Businesses using autonomous, intelligent agents are already experiencing better efficiency, lower costs, more quality control, and a shockingly high increase in production. Although initial expenses and skill limitations still exist, a planned, strategic strategy combined with appropriate technological alliances can overcome these obstacles.

Agentic AI will be the key difference of the next decade, elevating early adopters as leaders in operational efficiency, environmental sustainability, and innovations. Delaying Agentic AI adoption puts manufacturers at risk of missed opportunities for profitability and expansion in today’s highly competitive market. To stay ahead, businesses must align with experts who can guide them through this shift like Tredence’s AI Consulting services, which help enterprises strategically implement intelligent solutions that drive measurable outcomes.

Explore Tredence's advanced AI and analytics solutions, which turn your data into actionable outcomes. Contact Tredence to see how your organization can strategically employ Agentic AI to future-proof manufacturing operations.

FAQs

1. How does Agentic AI improve factory automation and robotics?

Agentic AI enables machines to freely adapt, make real-time decisions, and continuously maximize their performance to improve manufacturing automation and robotics. This increases accuracy, productivity, and efficiency while lowering manual control.

2. Can Agentic AI optimize supply chain management in manufacturing?

Agentic AI independently controls supply chain operations by dynamically changing inventory levels, real-time logistics optimization, and prediction of interruptions. This lowers inventory costs and improves market demand response.

3. How does Agentic AI enable predictive maintenance in industrial settings?

Agentic AI analyzes equipment data in real time to predict possible faults or malfunctions. It independently schedules maintenance tasks to minimize downtime, lower running costs, and extend equipment life.

4. Is Agentic AI suitable for small and mid-sized manufacturing businesses?

Yes, Agentic AI can be scaled to fit the needs of small and mid-sized manufacturers. With modular deployments and cloud-based solutions, even growing businesses can implement intelligent agents for tasks like predictive maintenance, inventory forecasting, and quality control. Many platforms offer plug-and-play solutions with minimal infrastructure overhead, allowing companies to start small and expand as needed.

5. How secure is Agentic AI when integrated into manufacturing systems?

Agentic AI systems can be highly secure when implemented with proper data governance, access controls, and cybersecurity protocols. Leading platforms offer enterprise-grade security features such as encryption, role-based access, and audit trails. However, as these systems gain autonomy, manufacturers must also implement ongoing risk assessments and compliance monitoring to safeguard sensitive operations and data.

AUTHOR - FOLLOW

Editorial Team

Tredence