Supply Chain Risk Management is an essential discipline for businesses operating in the fragile global economy. Supply chain disruptions and external uncertainties cost organizations an average of $200 million annually, posing severe threats to a company's bottom line and reputation. Key risks include:

- Extreme Weather Events: Natural disasters disrupting logistics and production schedules.

- Economic Instability: Fluctuations in global markets affecting supply and demand dynamics.

- Political and Government Changes: Regulatory shifts and geopolitical tensions altering trade routes and supplier reliability.

- Ocean Freight Bottlenecks: Congestion at ports delaying shipments, affecting inventory levels.

- Supplier Inconsistency: Variability in supplier performance leading to unexpected shortages or quality issues.

- Quality of Raw Material: Inconsistent material quality often compromising product integrity and customer satisfaction.

Therefore, managing global supply chains in an increasingly uncertain world is extremely challenging. Today, business executives are concerned about the potential risks threatening their entire network flow and the economy.

What is Supply Chain Risk Management?

Supply Chain Risk Management is the process of identifying, assessing, and mitigating risks in a supply chain to ensure business continuity. It involves recognizing potential disruptions, evaluating their impact, and implementing strategies like supplier diversification and contingency planning to enhance resilience and maintain competitive advantage.

This blog introduces readers to supply chain risk management discourse among leaders, practitioners, and vendors alike and how to mitigate it.

Why is Supply Chain Risk Management Important?

Supply Chain Risk Management is crucial because it helps businesses prevent costly disruptions, protect revenue, and maintain customer satisfaction. By identifying and mitigating risks, companies enhance resilience, reduce operational costs, and gain a competitive advantage in an increasingly complex global market.

Decoding Modern Supply Chain Risks

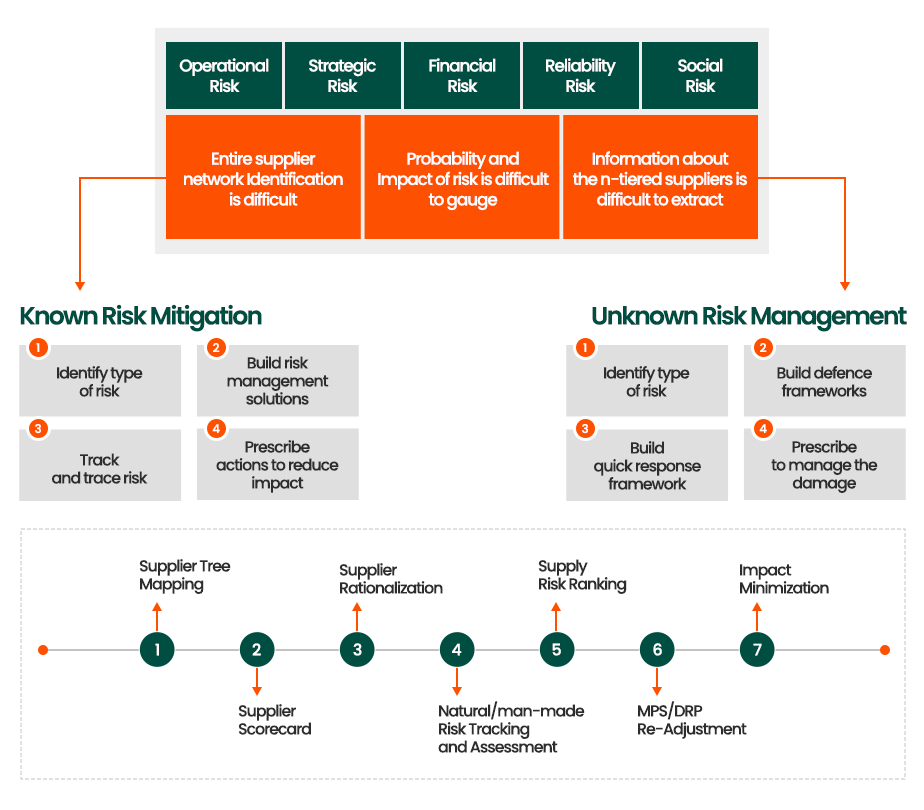

1. Supply Risk Management (or Unknown Risk Management)

1. Supply Risk Management (or Unknown Risk Management)

Supply risks are increasing as businesses face uncertainties in receiving raw materials on time, or at all, leading to significant drops in customer satisfaction. These risks are unpredictable and unmitigable, but they are manageable through strategic planning and risk management practices.

According to cips.org, supply chain disruptions in 2021 rocketed by 88% year-on-year in 2021. The top six disruptions were factory fires, mergers and acquisitions, business sales, factory disruptions, leadership transitions, and supply shortages.

The disruption category that experienced the biggest increase was supply shortages, which rose 452%. Labour disruption surged by 156%, extreme weather climbed by 130% and cyber-attacks increased by 143%.

Though risk assessment helps us identify where our vulnerabilities are so that we may better deal with potential setbacks when they do happen, these factors make it difficult to predict what will happen next in your company's supply chains without a plan. Therefore, a short-term tactical resolution is required to reduce the overall loss.

2. Supplier Risk Mitigation (or Known Risk Mitigation)

These risks build up over time and can be identified through historical patterns. To manage them strategically, businesses should change their supplier mix, diversify the supplier base, or add or remove suppliers to enhance resilience and reduce potential disruptions.

According to a survey, a third (34%) of firms have no idea how well their suppliers are functioning. Three quarters (73%) of respondents to the poll cited a lack of evaluation of the situation. The top reasons for not assessing suppliers were a lack of time (37%), lack of software (24%) and not feeling the need to do so (18%)

What is the need for an end-to-end supply chain risk management solution in the market today?

Many solution providers and product innovators have attempted to build a supply chain risk management solution. However, the majority of them are merely risk-sensing systems. Though such solutions might provide insight into the business's risks, most fail to quantify the downstream impact on the revenue and provide no recommendations to minimize the financial impact.

The need of the market is to have a solution that can:

- Map end-to-end supply chain with all the nth tier suppliers

- Identify the risks, both long term and short term

- Evaluate the downstream cross-functional impact on the supply chain

- Provide AI-based smart recommendations to minimize the impact

- Provide a collaboration platform to react quickly

- Provide approval workflow across the hierarchy

Today, it's critical for businesses to be prepared with solid planning to deal with both known and unknown risks. Tredence stands out when it comes to curtailing supply-chain disruptions while capturing the end-to-end value of your supply-chain strategy. Here’s a quick chart of what makes our Supply Chain Risk Management solution complete and unique –

|

Solution elements |

Tredence Solution |

Most of other Risk |

|

E2E Supply Chain mapping |

? |

? |

|

Global risk identification and prediction |

? |

? |

|

Risk assessment |

? |

? |

|

Cross-functional downstream impact of risk on supply chain |

? |

X |

|

Prioritization of risk to be managed - Immediate Vs. Distant, High Vs. Low Impact |

? |

X |

|

Simulation workbench - AI recommendations to minimize the dollar impact |

? |

X |

|

Platform to collaborate with various stakeholders and take corrective decisions |

? |

X |

Introducing Tredence Supply Chain Risk Management Solution

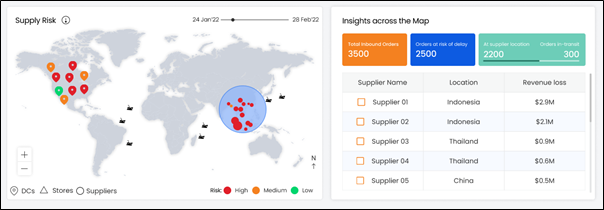

- Real-time data fetch to get factors indicating risk to the business

- Extreme Weather event history: For all the supplier locations - refreshed monthly

- Weather Forecast: For the same supplier location- refreshed each week. It captures fields for temperature, rain, snow and wind

- Port Congestion: For the supplier and receiver ports. It captures about 12 fields per port and is refreshed each week

- Traffic data: This is massive data fetch exercise. Refreshed weekly for more than a million data points for the route used for commute

- Social Media data: Download all the tweets, reports, and alerts from the select news handles and articles. It generates more than 200k data points from all the different handles

- Quantify and qualify the downstream impact on the supply chain:

-

- Our solution will effectively link unplanned events like weather disruptions, geo-political instability to potential supply chain network disruptions

- Eg., heavy storms in Southeast Asia could reduce the capacity of my primary supply base by 60% for three weeks

- In planned or unplanned events, this solution provides connected insights into the impact of supply chain disruptions (across areas like transportation, store operations, DC operations, fulfillment, etc.) hence providing a holistic idea of the impact and $ values involved.

- Eg., 60% risk to my inbounds supplies could lead to

- Reduction in OTIF by 22% for certain key categories

- Predicted excess in transportation capacity by 4% and Warehouse labor capacity by 6%

- Potential revenue loss of $500K

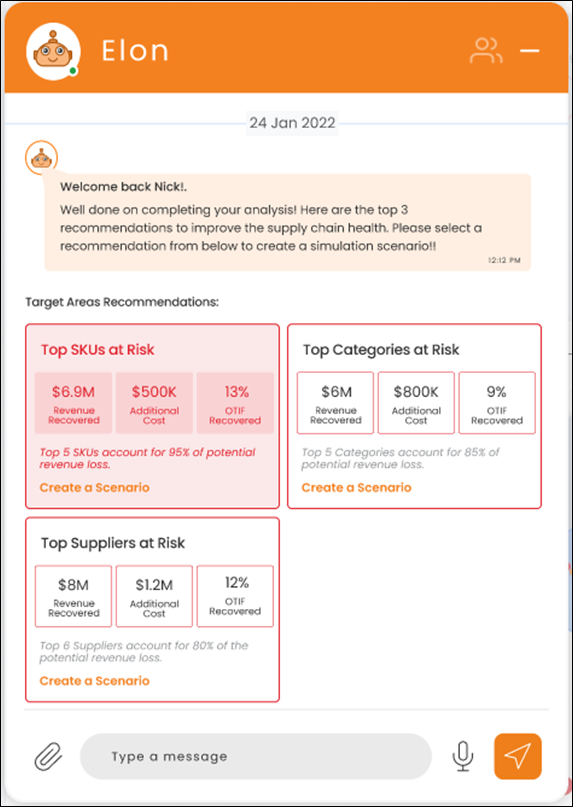

- Resolution recommendations & Scenario planning:

-

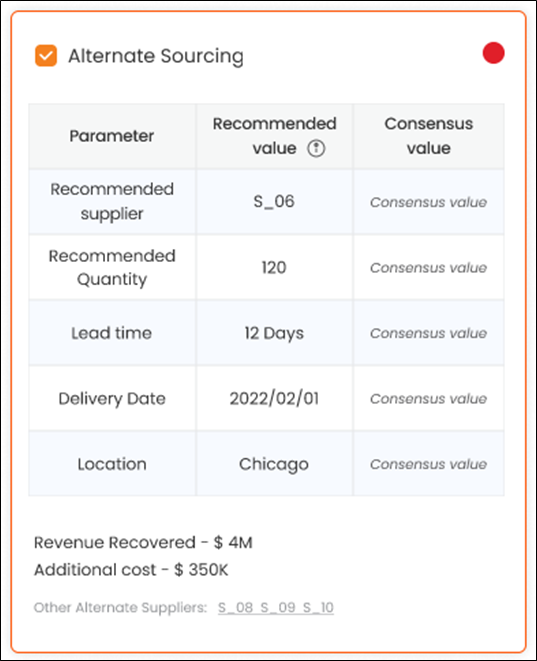

- “Cross-functional Scenario planning” helps analyze multiple solution options and choose options with the best all-round performance across the value chain

- AI-driven recommendation engine helps predict issues and recommends best actions by analyzing various scenario options

- Eg., What are solution options available to mitigate the situation - Expedite shipments, inter DC shipment transfer, or Alternate suppliers?

-

- Scenario planning to run multiple scenarios and determine trade-off analysis

- Eg., I want to target max service level of only key items, or I want to target a certain OTIF across categories/items

- Option A: provides overall OTIF of 75% at X USD additional cost | Option B: provides overall OTIF of 90 % at X+Y USD additional cost

- Eg., I want to target max service level of only key items, or I want to target a certain OTIF across categories/items

- Scenario planning to run multiple scenarios and determine trade-off analysis

Conclusion: The Future of B2B Industry Lies in Intelligent Supply Chain Risk Management Solutions

The recent global challenges, including the pandemic and geopolitical tensions, have underscored the urgent need for resilient supply chain networks. Companies must adopt strategic and tactical approaches to effectively manage immediate and long-term risks. Implementing comprehensive supply chain risk management solutions is essential for safeguarding operations and ensuring business continuity.

For more information on Tredence’s Supply Chain Management solutions, please visit: https://www.tredence.com/services/supply-chain-management

AUTHOR - FOLLOW

Shubhankit Verma

Senior Manager, Supply Chain Practice

Topic Tags